Previous

Next

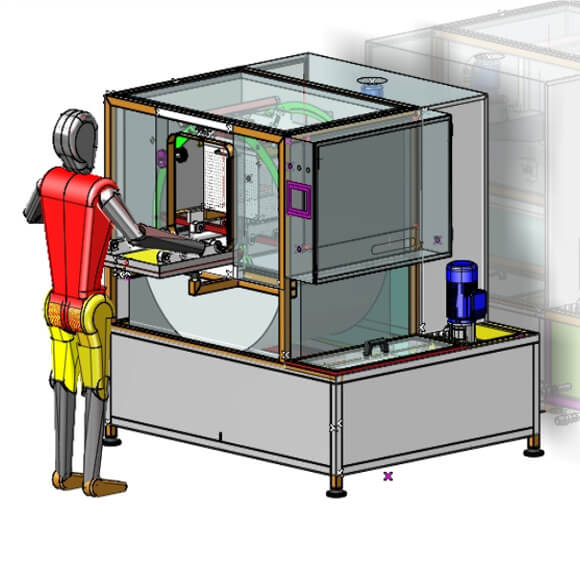

MRO 200 – MRO 400

Automatic washer with rotating drum on the horizontal axis. Immersion wash with flux.

Suitable for mechanical parts, degreasing, chip removal, drying.

Industrial washer with rotating drum for washing small metal parts (brass, steel, aluminum) having a complex shape and geometry, dirty with oil, grease, polishing pastes, machining shavings. The machine is entirely made of stainless steel with tubular bearing structure.

Programmable wash cycle:

- spray phase fed by a vertical pump immersed with aisi 304/316 stainless steel jacket, shaft, diffuser and impeller.

- immersion iphase in the same solution with a continuous flow of water that allows the internal parts, blind holes, small parts with complicated geometry to be washed.

- Drying / dripping phase with compressed air blade

- Drying phase with hot air (optional)

- Steam suction phase

The machine is equipped with an external basket filter so as to facilitate maintenance and cleaning operations. Loading operations take place in front of the machine by opening and tilting a stainless steel door.

Technical data MRO 200

- Dimensions: 1620 x 1690 h 1640

- 2 baskets: 450 x 300 h 180

- Washing pump: 2,2 Kw, 200 l/min verticale

- Tank: 350 l

- Heat: 4 heaters 4 Kw each

- Temperature: adjustable 0-80°C

- Motorized rotation: 0,18 Kw, adjustable de 1,5 à 3 tr/min

- Allarme: Low level/ filter clogged

Technical data MRO 400

- Dimensions: 1850 x 1780 h 1750 mm

- 2 baskets: 450 x 380 altezza utile 300

- Washing pump: 2,2 Kw, 200 l/min verticale

- Tank: 450 l

- Heat: 4 heaters 4 Kw each

- Temperature: adjustable 0-80°C

- Motorized: 0,18 Kw adjustable de 1,5 à 3 tr/min

- Allarme: Low level/ filter clogged

Optional

- Coalescence oil separator

- Hot air oven drying

- Reduction baskets for small parts

- Ultrafilter from 100 up to 5 microns

- Diaphragm pump for tank emptying

- Automatic water / detergent load