Ellegellemachinery

Construction and sale of stainless steel washing machine

HISTORY:

1972 -The Ellegelle company was born. From the idea of three founders specialized in manufacturing and welding of stainless steel, the company was formed for the construction of machines and plants for the food and catering industry.

1982 – Following the continuous request of machines, the present site of 2500 square meters is built in an area of 3000 square meters in Gerenzano (Va). Production processes are implemented with the purchase of automatic CNC machines for cutting, bending and welding of stainless steel sheet.

1995 – A new office building was build, where the sales and technical office are based dedicated to the design and development of plant and machinery following the request of the customers.

2000 – The children of one of the founding members take the company into thei own hands. The experience gained and the contribution of the new generation lead to the development of metal washing and part washing plants for the mechanical industry in general.

2006 – With the aim to offer an even more coplete service to the customrs, a new 500 sq.m. unit was open to support the existing one. The new unit includes a warehouse and a showroom where it is possible to view and do washing tests.

Ellegelle was born

New location in Gerenzano

New Commercial Building

New generation

New Tile Unit

Workshop parts washer

Parts washer for car and industrial vehicles maintenance

Mould Washing

Mould Washing plants

Wash small metal parts

Washing of small parts for industrial turnery and grinding

Chemical Industry

Washing plants for chemical and textile industry

Washing plant for nuts and bolts

Washing and passivating plant for nuts and bolts

Mechanical and aviation industry

Washing plant for mechanical and aviation ndustry

Planning

Fast and dynamic organization able to satisfy customer requests

ELLEGELLE machinery designs machines and plant in stainless steel for the washing and degreasing of metals and mechanical parts in general, characterized by its agile and dynamic organization capable of responding promptly to customer requests.

The technical office is equipped with parametric 3D CAD stations in order to visualize and define all the functional aspects of the project, feasibility analysis and cost, making available the thirty-year experience acquired.

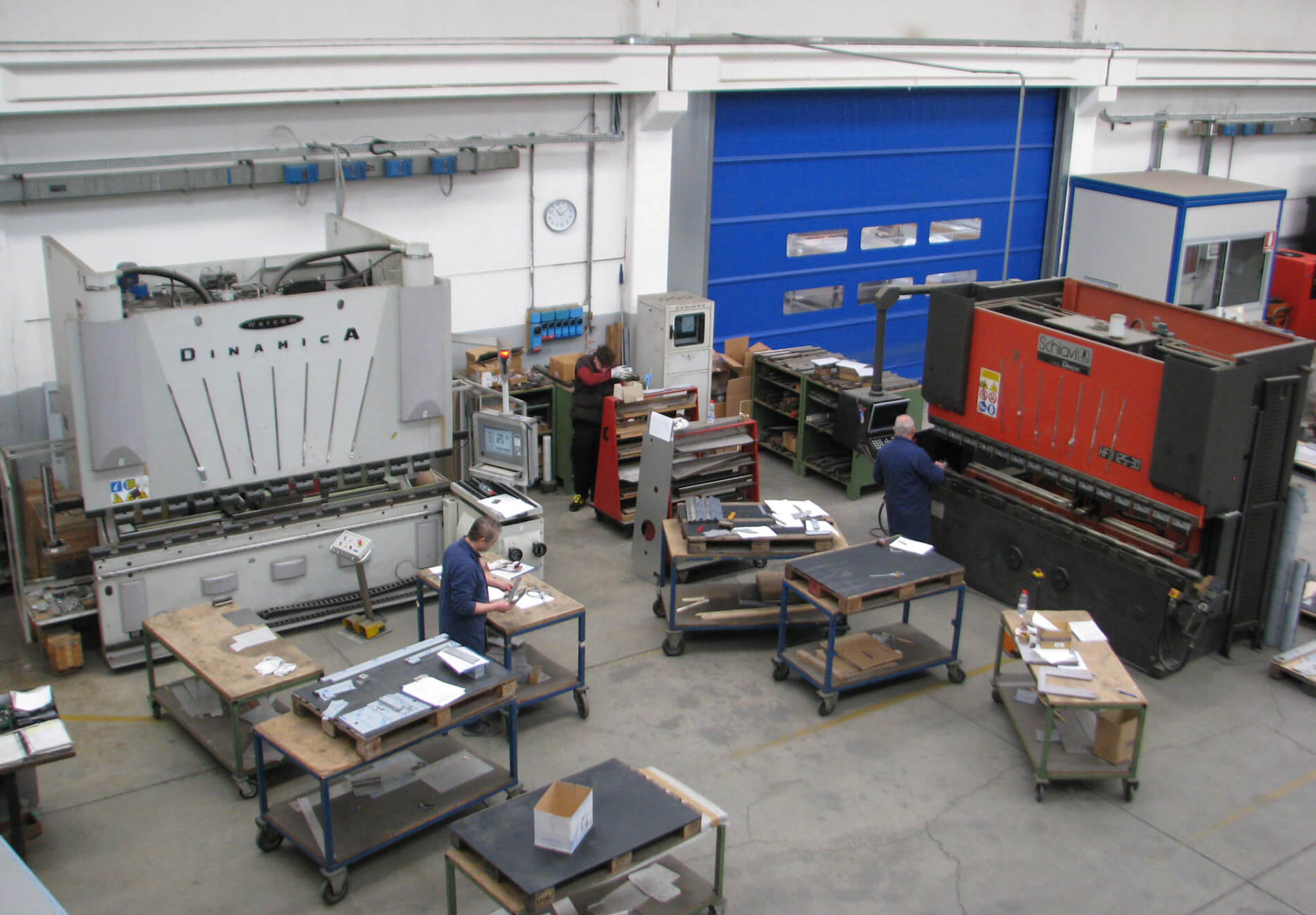

Production Department:

The interfacing of the CAD stations with the on-board machine CAM systems in the production department ensures a high quality and flexibility in adapting the customer's needs with the construction processes. The production department is also equipped with technologically advanced machinery such as laser, punching machine, CNC bending presses, assembly stations and TIG welding. This guarantees a high standard of processing of all the components.

Showroom

ELLEGELLE has created a dedicated area to assess the potential and functional aspects of the machines.

Our technical staff is always available to carry out washing and degreasing tests of the parts in order to identify the most suitable washing system for the customer’s needs.