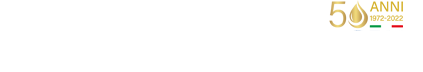

CR 900 – CR 1200

Automatic single-stage spray washer with motorized rotating basket.

Suitable for medium-sized heavy parts.

Automatic single stage spray washer with motorized rotating basket, entirely made of stainless steel with bearing structure in steel tubular suitable for intensive use.

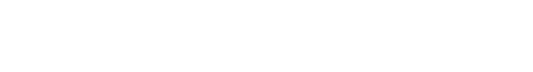

Washing takes place by crossing two spray ramps with a solution of water and detergent at a maximum temperature of 60°C. Each ramp is composed of lower, lateral and upper pipe and is fed by a vertical immersed pump equipped with aisi 304/316 stainless steel jacket, shaft, diffuser and impeller and is maintenance-free. The washing solution is then filtered and collected in the tank to be reused until it is completely exhausted. The machine is equipped with a basket filter externally positioned in order to facilitate maintenance and cleaning operations. Loading operations take place in front of the machine by manually opening the flap of a stainless steel door; the opening is assisted by 2 gas springs.

- Dimensioni: 1580 x 1150 h 1250

- Cestello: diametro 900, altezza utile 550 mm

- Carico utile: 400 Kg

- Pompa di lavaggio: 1,5 Kw, 120 lt/min verticale

- Pressione di lavoro: 4 bar

- Serbatoio di raccolta: 120 lt

- Riscaldamento: n.2 resistenze 4 Kw/cad.

- Temperatura: regolabile 0-60°C

- Rotazione motorizzata: 0,18 Kw, 5g/min

- Allarme: minimo livello; filtro intasato

- Dimensions: 1960 x 1500 h 1350

- Basket: diametro 1200, altezza utile 630 mm

- Charge utile: 600 kg

- Pompe de lavage: 2,2 Kw, 200 lt/min. verticale

- Pression de service: 5 bar

- Réservoir de collecte: 250 lt

- Chauffage: n.3 resistenze 4 Kw/cad.

- Température: regolabile 0-60°C

- Rotazione motorizzata: 0,18 kw, 4 g/min

- Allarme: minimo livello; filtro intasato

- Coalescence oil separator

- Drying oven

- Ultrafilter from 100 up to 5 microns

- Electric fan for steam extraction

- Insulation for T 80C °

- Removable basket on external trolley

- Emptying diaphragm pump

- Electrical panel with PLC touch screen

- Automatic water filling with detergent dispenser

- Dripping with compressed air blade

- Automatic opening with pneumatic pistons