GE 1200-2X GE 1500-2X

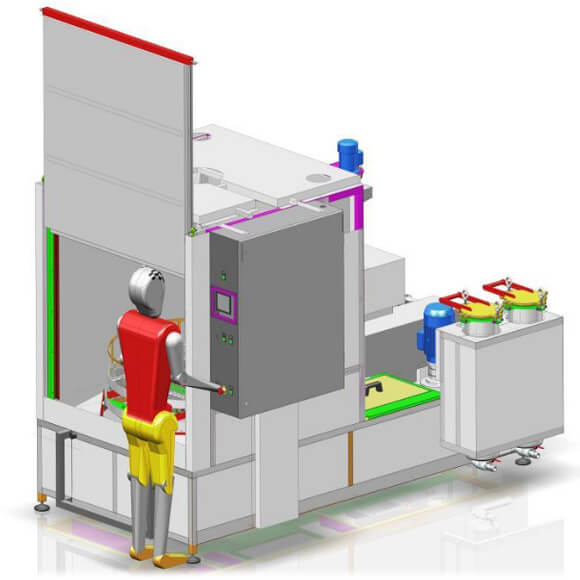

Spray washer, double tank for washing and rinsing with removable rotating basket on stand or external trolley.

Opening with pneumatic pistons, suitable for very heavy and bulky parts.

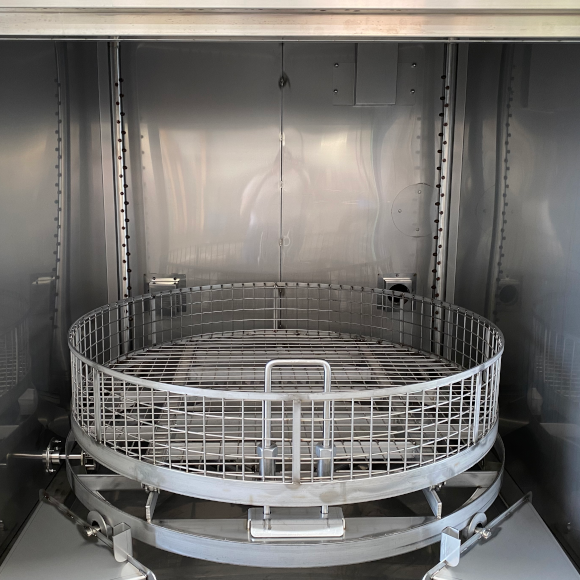

Industrial automatic double-tank spray washer, with motorized rotating basket, entirely made of stainless steel with tubular bearing structure.

Washing is carried out with a solution of water and a biodegradable detergent by crossing a spray ramp fed by a vertical pump with stainless steel aisi 304/316 jacket, shaft, diffuser and impeller, maintenance-free pump. The washing temperature reaches 80°C with minimum energy expenditure thanks to the complete insulation paneling and it is a guarantee of an excellent result in washing even dry grease with considerable resistance. This temperature also facilitates rapid drying of the piece. The solution is collected in the tank and re-used until its complete exhaustion.

Rinsing occurs in the same way as with the washing machine but with a separate tank, pump and piping. The machine is equipped with an exchange system suitable for keeping the washing water separate from the rinsing water.

Loading operations take place in front of the machine by opening the door with pneumatic pistons and bi-manual push-button panel

- Dimensions: L2500 x P1700 h 2100

- Loading basket: Diameter 1200 mm H utile 850 mm

- Load max: 650 kg

- Washing/Rinse pump: 4 Kw, 350 l/min.+4kw 350lt/min

- Pressure: 4 bar

- Tank: 300 l + 300 l

- Heat: 4+4 heaters 4 Kw each

- Temperature: adjustable 0-80°C

- Alarm: Low level/ filter clogged

- Dimensions: L2900 x P2200 H 2100

- Loading basket: D 1500 h utile 850

- Load max: 1000 Kg

- Washing/Rinse pump: 5,5 400 l/min + 5,5 400 lt/min

- Pressure: 3,5 bar

- Tank: 500 l + 500 l

- Heat: 5+5 heaters 4 Kw each

- Temperature: adjustable 0-80°C

- Alarm: Low level/ filter clogged

- Manual extraction of basket on exterior trolleys

- Automatic basket extraction on support

- Drying with hot air oven

- Emptying diaphragm pump

- Oil skimmer

- 100 to 5 micron ultrafiltration

- Automatic water/cleaning loading product